Hydrogen, particularly 'green' hydrogen derived from renewable sources, stands as a crucial milestone in the journey to decarbonize heavy industries and the mobility sector. The demand for green hydrogen is present and will increase even more in the upcoming years.

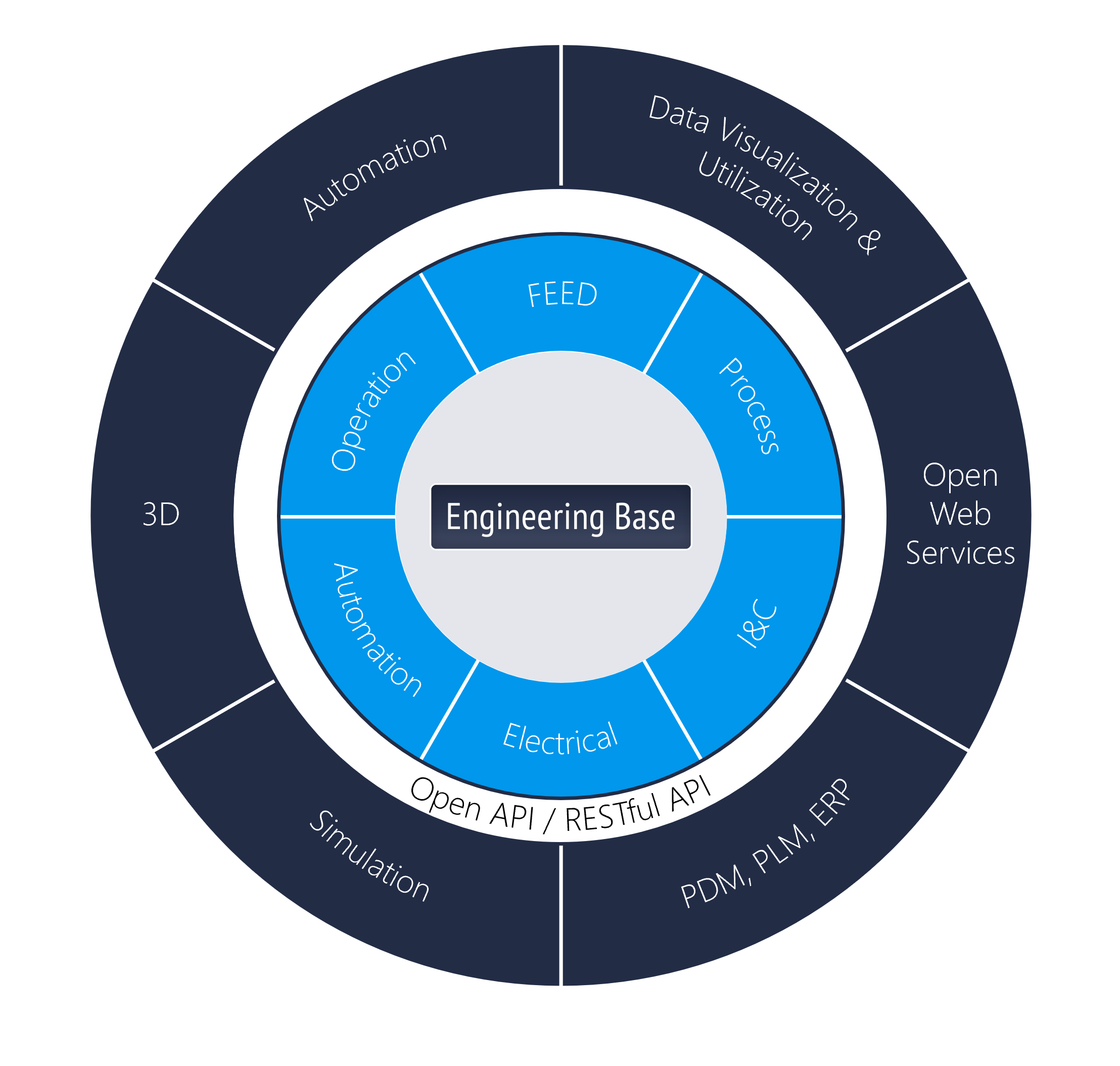

As an engineering software developer with extensive experience in the power and process industries, AUCOTEC is strongly committed to supporting and accelerating the Green Energy Transition. Our instrument for that: Our data-centric engineering platform, Engineering Base (EB). The platform is designed to transform traditional, rigid processes into a dynamic, digital, and interconnected way of working and supports companies to significantly shorten project timelines, enhance quality, mitigate risks, and consolidate valuable know-how throughout complete project lifecycles.

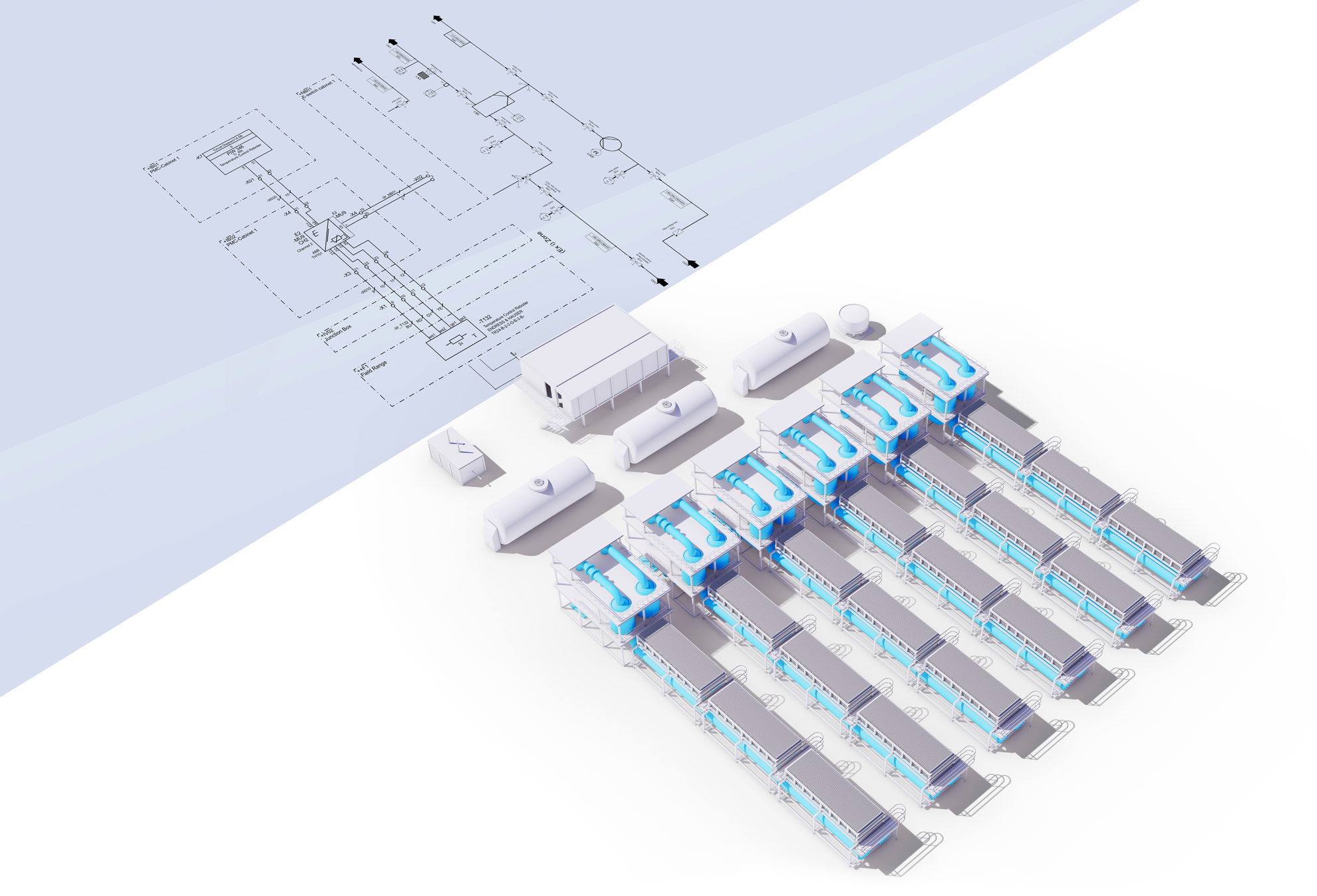

Data-centered modularization with Engineering Base (EB)

Engineering Base (EB) provides a consistently reliable data model that serves an ideal basis for standardization and modularization in the hydrogen sector. The software's unique architecture facilitates straightforward upscaling scenarios and global collaborations. Furthermore, the software's user-friendly interface and minimal customization requirements make it an excellent fit for the growing market. To learn more about AUCOTEC's solution, visit the Hydrogen showroom.Hydrogen Showroom

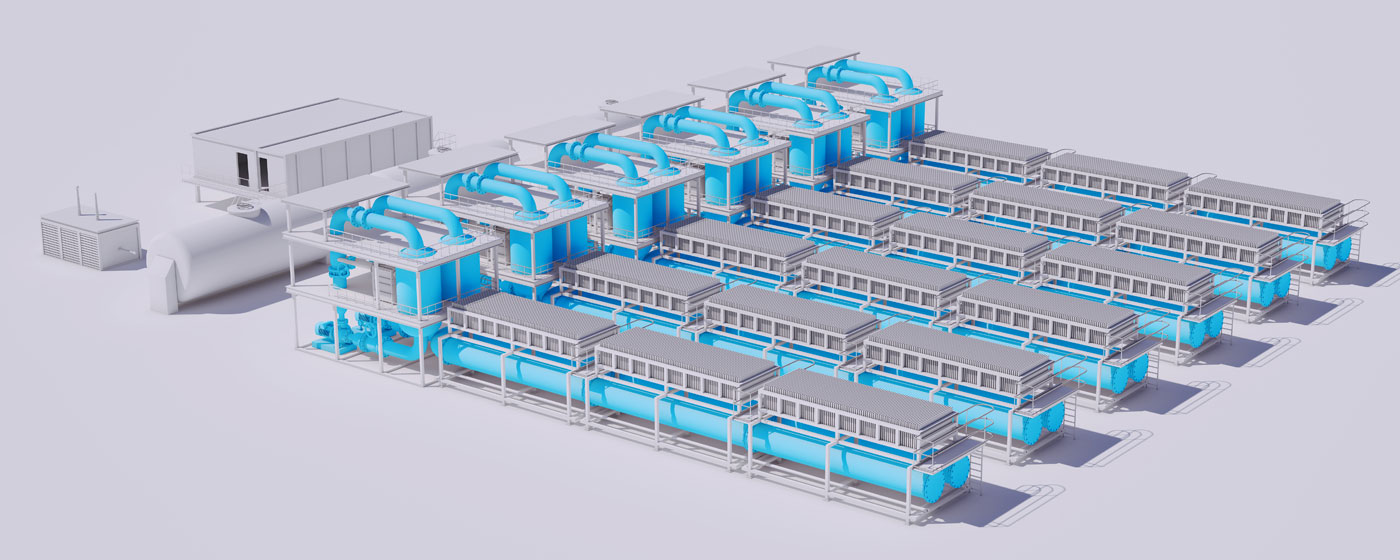

More hydrogen plants in less time with data-centered modularization

In addition to advancements in electrolysis technology, optimizing engineering processes for hydrogen electrolysis plants is a key driver for enhancing efficiency. By employing cross-disciplinary engineering solutions, integrated with a smart modularization approach, project durations for electrolyzers can be significantly reduced.AUCOTEC CHEMIE TECHNIK H2 View

Sunfire: Efficiently producing more green hydrogen with EB

Sunfire, a technology leader in the field of green hydrogen, plans to significantly increase its electrolysis capacities with the support of Engineering Base (EB). The solution will support Sunfire to unify the software landscape, to collaborate with all engineering disciplines on one consistent data model and to accelerate project lifecycles. EB's capability of data-centric modularization throughout the engineering value chain will be a key element in reaching this goal. Read more here

EB’s data centricity is a milestone for Topsoe’s Engineering

More projects, lower costs: EB’s focus on data-centricity is a milestone for Topsoe’s Engineering. As a leading supplier of catalysts and green technologies, TOPSOE has chosen to rely on Engineering Base (EB) as the central engineering system for the development of new plants. Through EB, TOPSOE has ushered in a new era of digital, collaborative engineering, enhancing both quality and flexibility while realizing significant cost savings of around 10%.Read more here

One versatile data model from FEED to Operation

Designed for EPCs, plant manufacturers, contractors, and owner-operators, Engineering Base (EB) streamlines the design process and ensures seamless continuity from FEED to Process and Detail Engineering of process-oriented plants. The software's corresponding data model represents the highest level of digitization - Each object exists only once in it, and diagrams, datasheets and lists are only different representations of the same object. This allows for all departments to edit and detail the object from their unique perspective, with each addition directly visible to all parties without the need for interfaces, data transfers, or transmission errors. As a result, EB enables natural consistency throughout the design process. Learn more about EB on our website.Read more here

H2-ready? EB as key element

Modularization is key – especially when it comes to standardized modules in the electrolyzer business. Find out, how Engineering Base (EB) and it´s modularization capabilities can assist electrolyser manufacturers to quickly produce more systems for more megawatts in the AUCOTEC Infopaper 1/2024, page 2.Download infopaper

Our Expert

Niclas Meier is Global Account Manager and hydrogen expert at AUCOTEC. "In addition to large-scale plant builders or operators, our software can also support customers who want to assign their projects more to the product world and work with highly standardized modules to 'click together', for example function-oriented assemblies. For this, Engineering Base offers an extremely intelligent solution."Get in touch!